Introduction

A commercial kitchen tool called a sev manufacturing machine prepares sev, a well-known Indian snack composed of gram flour, spices, and oil. Businesses that require a lot of sev can benefit from this Machine’s ability to create a lot of sev quickly.

There are several varieties of sev-making equipment on the market, and each type has benefits and drawbacks of its own. We will go into great detail about the top sev-making machines in this post.

What is Sev making a Machine?

An industrial or domestic device known as a sev maker is used to create sev, a famous Indian snack made from chickpea flour.

The apparatus comprises a hopper into which the sev dough is put, a motor that pushes the dough through a die, and a cutting mechanism that shapes and sizes the sev strands as needed.

The machines used to make sev come in various shapes and sizes, including hand-operated, motorized, continuous, extrusion, automated, multi-purpose, vertical, batch, and pedal-operated models.

Types of sev making Machine

Hand-Operated Sev Machine:

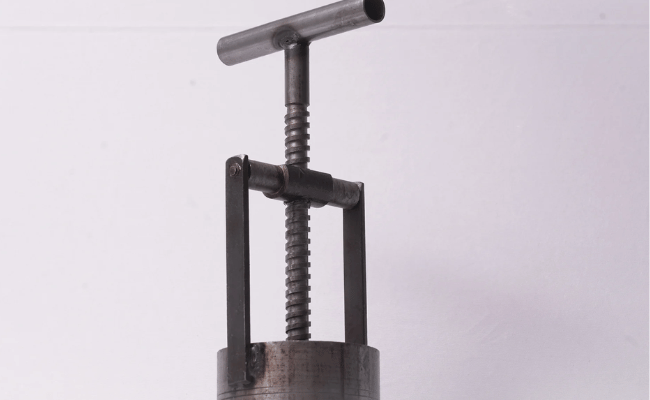

Using a hand-operated Sev-making Machine is the most basic method of manually operating a machine for manufacturing Sev.

The components of this device are a hopper, a die, and a handle. The sev dough is placed into the hopper by the operator, who then twists the handle to force the dough through the die to form long strands of sev.

Motorized Sev Machine:

A motorized sev machine is a more sophisticated variation of a hand-operated sev machine. The dough is forced through the die by this Machine’s electric motor, producing several strands.

This kind of Machine can create a greater volume of sev in less time and is quicker and more effective than hand-operated equipment.

Continuous Sev-Making Machine:

Stainless steel is generally used for continuous sev-producing machines, which exist in various sizes and capacities.

They require very little manual involvement because they are automated. They are perfect for enterprises that demand a high volume of sev production since they can create a lot of sev quickly.

Extrusion Sev Machine:

An extrusion Sev making Machine is a particular kind of sev-making device that produces sev through the extrusion technique.

A hopper, a motor, and a die specially made to have sev strands of various diameters and shapes make up the Machine. Long strands of sev are created by pushing the sev dough through the die with a screw.

Automatic Sev-Making Machine:

A completely automated machine that can make sev without any operator input is known as an automatic sev-making machine.

The sev dough is transported by the Machine’s conveyor belt to a mixing room, where it is combined with other ingredients and spices.

A die extrudes the mixture, producing strands of various lengths and forms. Automatic sev-making machines are appropriate for large-scale manufacturing since they can crank out a lot of sev quickly.

Multi-Purpose Sev producing Machine:

A multi-purpose sev-producing machine is a flexible device that may produce wide variety of sev and other foods, including noodles, papdi, and bhajia.

The Machine consists of many dies that can be switched out to grow food in various sizes and shapes. Businesses that need to make a range of snacks might benefit from multi-purpose sev-making equipment.

Vertical Sev Machine:

Because of their small size and portability, vertical Sev-making Machine is ideal for use in confined areas. The sev dough is poured into them through a tiny aperture at the top of a steep, cylindrical drum.

When the drum is turned, the sev dough is forced through the small, irregularly shaped holes to produce sev strands of various sizes and forms.

Batch Type Sev Machine:

Machines that manufacture sev in batches are known as batch-type sev machines. They are made of a hopper for loading the mixture and a mixing chamber where the sev dough is combined with spices and other ingredients.

After that, the mixture is forced through a die to produce sev strands of various lengths and forms. Businesses that need a considerable volume of sev production should use batch-type sev machines.

Conclusion

The ideal sev-making Machine will rely on the company’s demands for output. A hand-operated sev machine is excellent for small-scale manufacturing, while a motorized Sev making Machine is ideal for medium-scale work.

A continuous sev-producing machine is a perfect choice for large-scale manufacturing. However, it is crucial to consider aspects like production capacity, usability, maintenance, and cost-effectiveness before purchasing a sev-producing machine.

Also Check: Why is Everyone Obsessed with the Spice box?

Comments