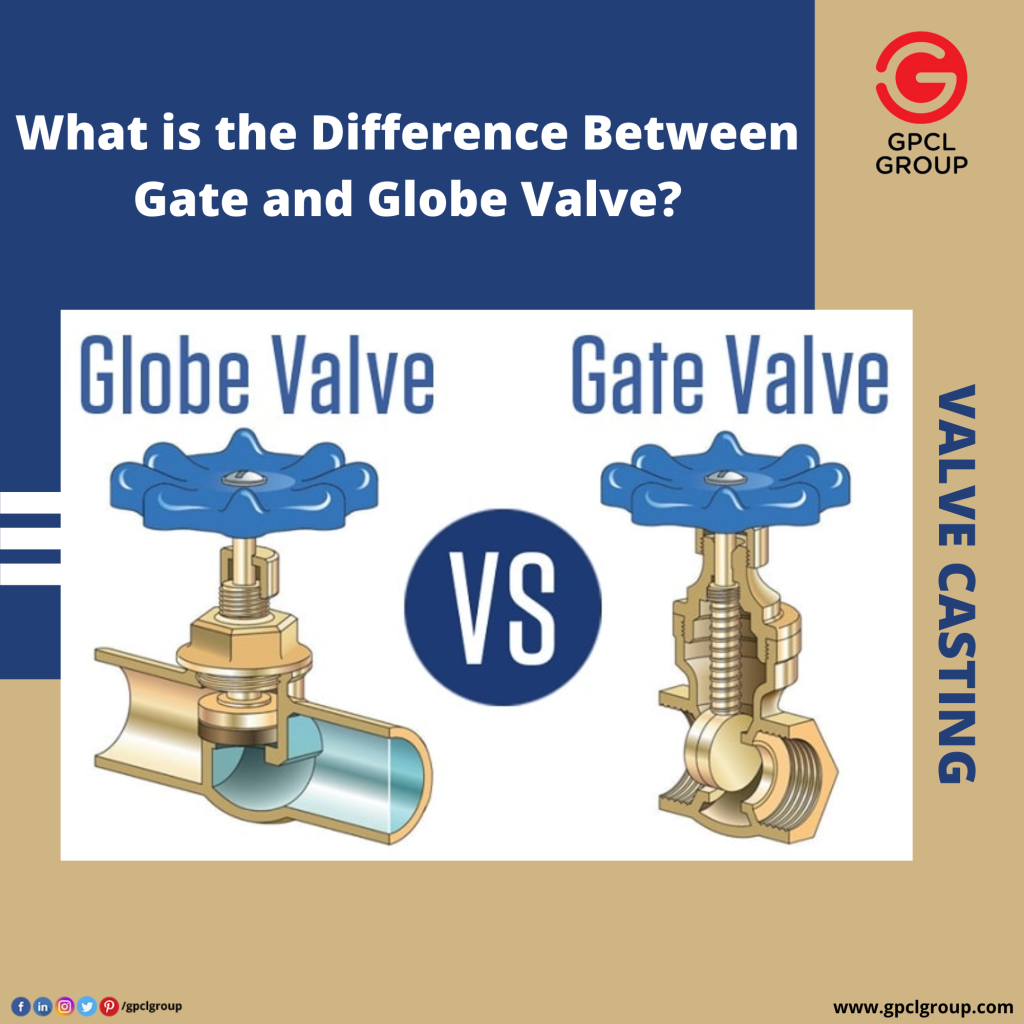

The valve casting manufacturers are employed to start, stop, and control the flow of fluid. The two types of valves that are most frequently utilize are globe and gate valves. The primary distinction here between a gate valve and a globe valve is in the way they are built and function. Specifically, this essay contrasts the Gate valve with the Globe valve.

Overview of Gate Valve :

The fluid can be hermetically sealed by a wedge-shaped gate on it.

Most often, the fluid is isolated using gate valves. They cannot be used to control the flow of liquids. These are used in services that demand tight sealing as a result.

The gate valve doesn’t cause obstacles as the fluid flows and has a very low-pressure loss. To open and close the flow, it features a gate disc that oscillates up and down. Its design options for this gate disc include parallel, wedge, and knife.

Overview of Globe Valve :

The flow can be opened, closed, or throttled using the globe valves. They are a member of the linear motion valve family. This valve opens or closes the flow using a disc or plug.

The globe valve got its name from how the standard housing looks like a globe. Its construction minimize the possibility of leaks while offering a tight seal.

These valves have a higher pressure drop than gate valves, which is one of their primary drawbacks.

Because the seat of this valve is parallel to the liquid dynamics, seat corrosion is minimize when the valve opens. This valve’s configuration makes it a superb throttling valve.

These globe valves are employed in systems where leakage prevention and safety are top priorities.

The difference between Gate valve and Globe Valve:

The following list outlines the primary distinctions here between a globe valve and a gate valve:

A gate valve casting manufacturers and a globe valve differ mostly in terms of design. The gate valve has an uncomplicated design compared to the globe valve’s intricate construction. The globe valve’s internal parts are fitted inside the valve. As a result, the construction of these valves is intricate. A rising stem can be seen in the globe valve. These valves come with rising or flat stems.

This is because the gate valve’s internal parts are fitted inside the valve chamber. The valve chamber doesn’t hollow out as the globe valve is switched on. A high-pressure drop results from this.

On the other hand, the gate valve’s internal components are situated on the valve body. As a result, the gate valve body appears hollow as it opens, allowing flow to travel through the valve with ease. The globe valve does have a minimal pressure drop as a result.

Compared to the globe valve, the gate valve casting manufacturers require less maintenance. The maintenance and repair of the globe valves are challenging. In comparison to the gate valve, they require more frequent maintenance.

The gate disc on the gate valve is very thin. A globe valve plug is not as thick and rigid as this gate disc. The gate disc may go out of alignment with its seat while the fluid is being throttled through the gate valve. As a result, you cannot throttle flow using gate valves. If you utilise it for throttle flow, this will quickly become damaged and have a limited lifespan.

Compared to the globe valve, the gate valve requires less maintenance. The maintenance and repair of the globe valves are challenging. In comparison to the gate valve, they require more frequent maintenance.

Also Read: All You Need to Know About the Blockchain Technology

Conclusion :

The gate valve’s narrow gate disc prevents it from being used to throttle flow. whereas the globe valve is more frequently utilised to throttle flow. Compared to gate valves, globe valves have a more complicated structure. More affordable than globe valves are gate valves.

Gate valves are better in fluid separation than globe valves. The globe valve casting manufacturers pieces are put within the valve body, while the inner portions of the gate valve are positioned on top of the valve body.

The gate valve has several directions. It may be mounted in any orientation. Globe valves, on the other hand, are unidirectional valves. The globe valve can only be installed in one way.

Comments